Our Processes

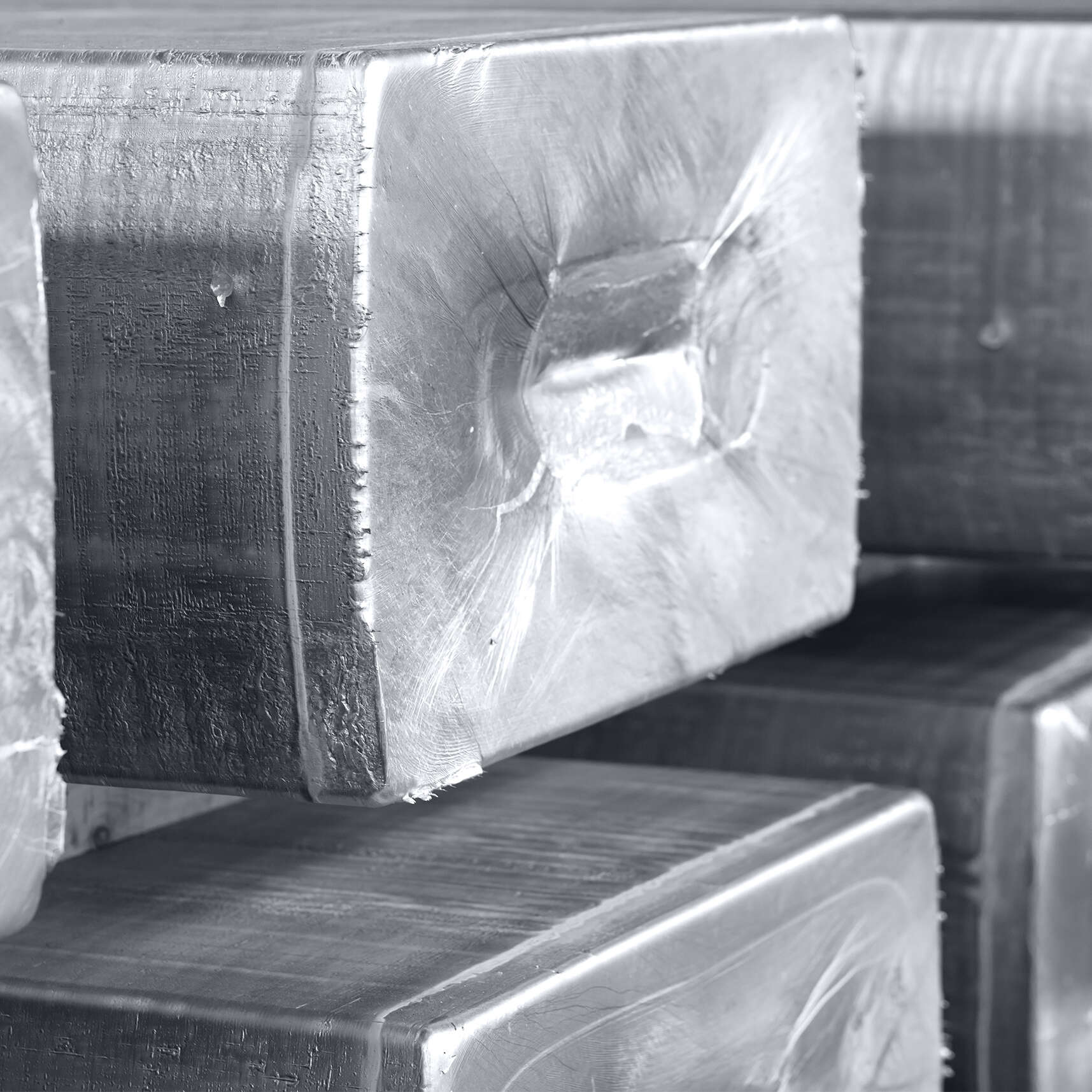

SMELTER

- Metallurgical Treatment Flows

- Degassing and metallurgical treatment plants

- Silicon carbide

- Casting Feeding Products

CASTHOUSE

We have protective products, refractory coatings and specialty lubricants; chemicals and lubricants.

Types:

- GRAIN REFINING

- ALLOYNG

- DEGASSING

- MODIFYING

- DEOXIDIZING

- DROSSING OFF

CASTING

Advantages:

- Fully synthetic

- Does not promote the growth of algae or bacteria

- Completely non-hazardous

- Very low levels of BOD and COD compared to natural esters

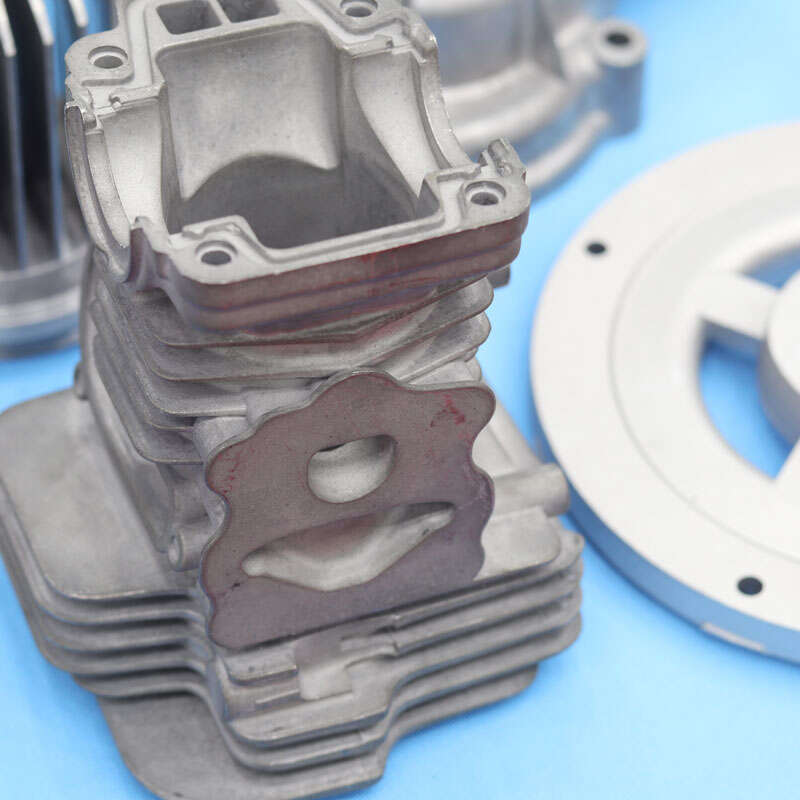

DIE CASTING

Reduced scrap due to stains, surface finish quality and porosity

Quality improvements are economic efficiency. Our release agents are designed to provide excellent release and optimized surface finish. Our experts can help you select the correct lubricant and application method to minimize scrap and produce paintable, adaptable parts with the desired appearance.

Reduce downtime for cleaning

Continuous casting machines require the use of clean and compatible products. Our release agents not only leave minimal residue on dies, cores, vents and feed lines, they also remove waxy and oily residue left by other release agents.

Large operating windows

Heat release agents tolerate a wide range of mold temperatures and a variety of part complexity. They also increase tolerance to variations in other processes, ensuring low environmental, health and safety issues.

Low environmental, health and safety issues.

Respect for the environment and the health and safety of the operator are fundamental in everything we do. Incorporating features such as low smoke, no phenols and bad odors, our products are pleasant to use and environmentally friendly.

• Quantified productivity improvements

• Reduced scrap speed

• Improved appearance

• Parameters for definitive troubleshooting.

MOTHER ALLOY AND MELTING POWDER

LOW PRESSURE AND GRAVITY

- Skinning

- Protective and refractory coatings, separation of lubricants

- Protecting for dies, cores, moulds

- Improve the sliding of metal

- Regulate the heat exchange

- Improve the extraction of the final product

- Provide a good surface finish

- Water or alcohol