Our processes

LAMINATION

ALUMINUM COLD ROLLING

- Excellent reduction capability

- Easy refrigerant preparation and control

- Constant rolling performance

- Absence of stains after annealing

- Meets AB and FDA requirements for accidental food contact

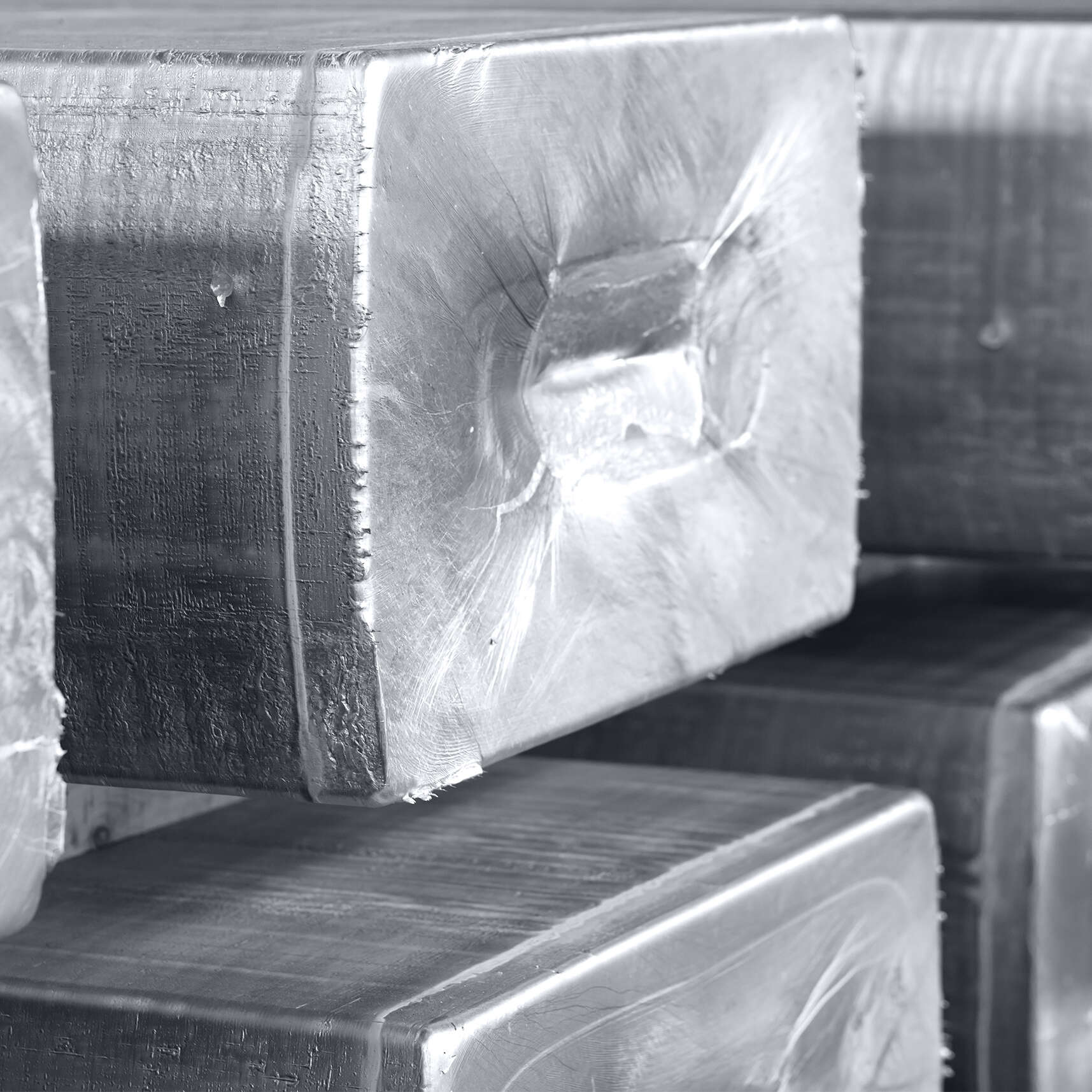

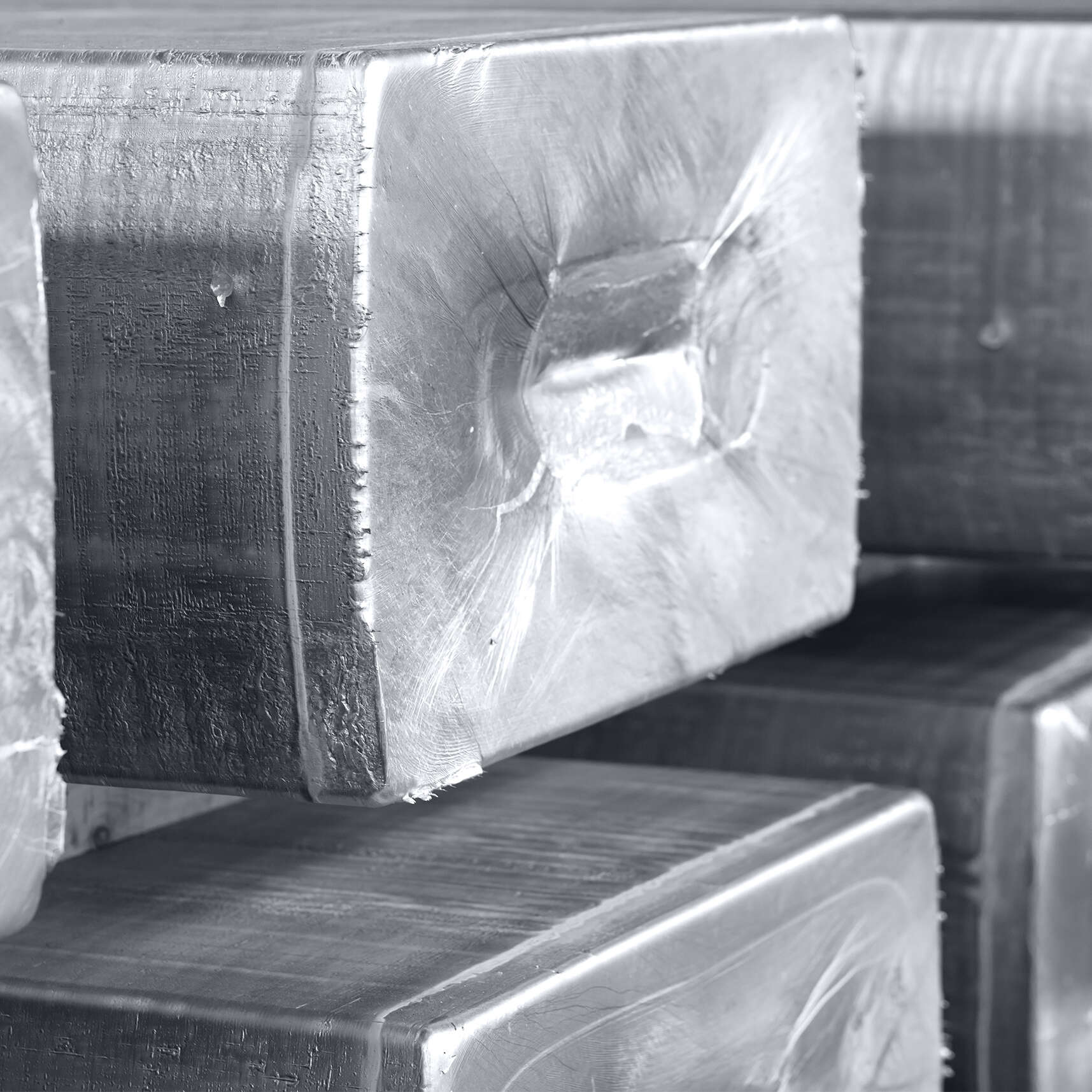

ALUMINUM HOT ROLLING

The ALFEMIL AR series product line is divided into special formulations for reversing and finishing hot rolling mills, based on the intrinsic differences in lubrication and emulsification between these types of mills.

ALFEMIL AR 1 series products are specifically designed to meet the demolition needs of today's individual stands and intermediate mills. This line also contains the products needed for the lubrication of combined reverse-finishing mills, designed to handle both ingot breakage and coil finishing.

Similarly, the ALFEMIL series products are specifically designed to meet the needs of multi-stand finishing mills with higher speeds and more critical surface quality requirements.

The ALFEMIL series takes into account the needs of continuous jet (single or multiple) fed hot mills.

ADVANTAGES:

- Limited content of free organic acids compared to traditional formulations, with consequent lowering of metal soap formation

- Good thermal separation under the rolling cylinders

- Excellent hydrodynamic lubrication conditions, high polarity and good film sealing at high lamination loads/pressures.

- Easy separation of polluting oils and other materials/products

- Stable oxide film formation on the laminating rollers in the first and intermediate steps and laminating condition with clean rollers during the final steps

COLD ROLLING STEEL

HOT ROLLING STEEL

- Sheets

- Wire Rods

- Bars

- Railroads

- Profiles

- Steel beams

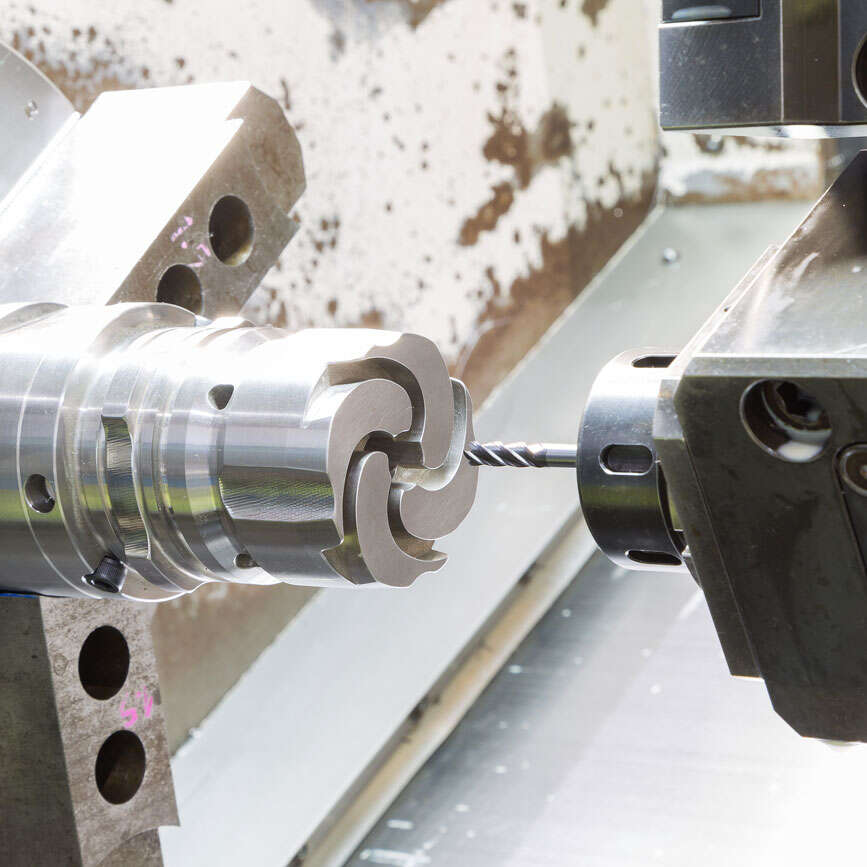

EXTRUSION

Extrusion provides parts with even more precise shapes than those possible with printing or forging. In addition, the parts produced show excellent surface conditions, often allowing them to be used in subsequent steps without further finishing.

Foundry Alfe CHEM offers a complete range of lubricants for extrusion and aluminum drawing, adapted to each of the operations from billet cutting to profile shaping.

Silverliquid

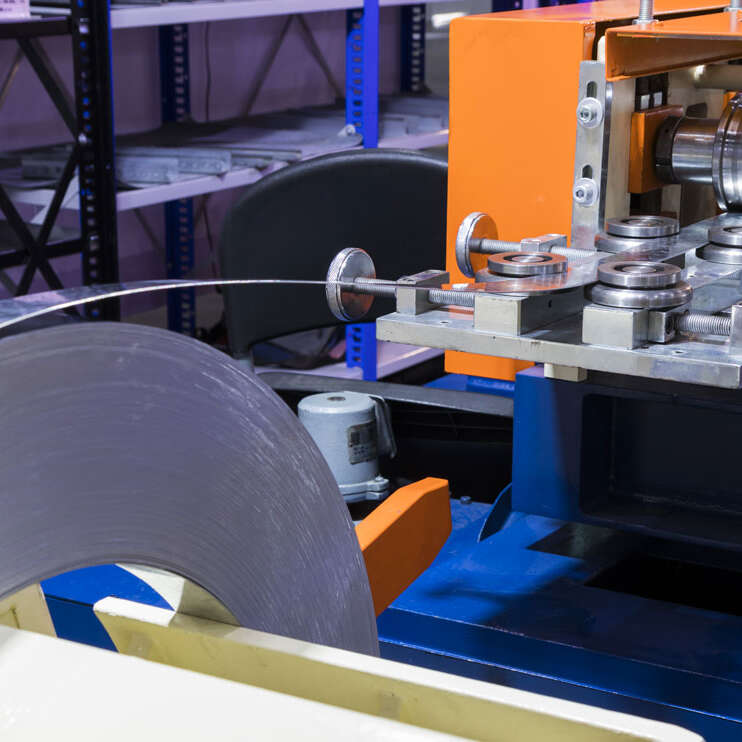

TRAFILING

A constant research work in collaboration with the manufacturers of drawing machines and components, guarantees a line of lubricants for every application, even the most advanced.

- MACHINES WITH IMMERSED DIES

- SPRAYING DIE MACHINES

- MULTIWIRE

- TANDEM

The ALFE DRAW WD series ensures a long life of the dies, as well as the protection of the wire and the plants against oxidation. Specific products have been designed for use in annealing machines to completely eliminate the risk of wire oxidation.

The use of ALWIRE allows to work at higher speeds or to perform more difficult machining operations.

In particular the TEMADRAW series is characterized by integral products for the production of straight tubes and coils, where high production speed is required as well as very low carbon residue, after annealing, and compatibility with modern cooling fluids.

DEEP MOULDING (HOT / COLD)

- Complete range of versatile products, suitable for light to heavy duty applications

- Reduced lubricant consumption thanks to reduced drag

- Excellent welding without prior cleaning

- Improved cleanliness and safety of the equipment

- Excellent surface finish

- Reduction of non-compliance

- Improved tool life

- Improved production process control

- Easy removal with alkaline detergents

- Mild odor and low fog formation (high compatibility with operators)

- Chlorine free products available

- Reduced Excellent surface finish

- Scrap rates

- Improved tool life

- Better control of metal flow

- Easily removed with alkaline cleaners

- Low odor and low mist; high operator acceptance

- Chlorine-free products available

ALUMINIUM CANS PRODUCTION

- Low applied costs

- Low maintenance

- Better can quality

CUTTING AND SCALPING

The Benefits:

- Non-staining

- Superior lubricity characteristics

- Extended tool and knife life

FORGING

GRAPHITE PRODUCTS

- Metal sliding

- Appearance

- Detach the printed piece

- Durability of the mold

- Thermal stability

GRAPHITE-FREE PRODUCTS

Significant benefits have been achieved in the production of aluminum and brass components by applying Foundry Alfe CHEM's advanced graphite-free formulations, which leave a clean surface finish. The ALFECAST range of graphite-free solutions and emulsions is usually applied by spray or hand buffer and forms stable solutions with a concentration of 3% - 10%, depending on the application.

METAL CUTTING AND GRINDING

REFRIGERANTS

- Exceptional lubrication

- Reliable rust protection

- Long life of the product in use

- Ease in wastewater treatment

- Excellent operator compatibility

- Long life of the product in use

- Excellent compatibility with the operator

- Easy elimination of foreign oil

- Excellent recyclability

- Versatile range, capable of a wide variety of processes

- Operations on a wide variety of synthetic metals

- Oil-free for clean operation and reduced mineral oil mist

- Easy removal of foreign oil on the surface

- Low foaming

NEAT OILS

TREATING

Stamping and cutting sheet metal and blank is a metal-forming procedure that allows production of parts with complex shapes. The use of new materials (HLE steel, ferritic stainless steel, aluminium) associated with increasingly important environmental constraints and cost reductions requires the use of high-performance lubricants.

Drawing on our technical expertise and our know-how in the field of cold metal-forming, we offer the ALFEDRAW range intended for cutting and stamping of metals.

Taking the HSE impact into account is an integral part of the technical specifications for our lubricants.

Foundry Alfe CHEM therefore offers alternative technologies and draws on bio-sourced raw materials. Improvement of working conditions is then possible thanks to the use of products without chlorine, without mists and without volatile organic compounds (VOCs).

A complete range of lubricants for cutting, punching, fine blanking, stamping, drawing with ferrous and non-ferrous metals.

Blanking and cutting of sheets and blanks is a metal forming procedure that allows the production of parts with complex shapes. The use of new processing materials (HLE steel, ferritic stainless steel, aluminum) associated with environmental constraints and increasingly stringent cost reductions, today increasingly requires the use of high-performance lubricants.

Drawing on our technical expertise and know-how in the field of cold forming of metals, we offer the ALFEDRAW range for metal cutting and stamping.

The consideration of HSE impact is an integral part of the technical specifications of our lubricants. Foundry Alfe CHEM therefore offers alternative technologies and draws on raw materials of biological origin. Improved working conditions are therefore possible through the use of chlorine-free, mist-free and VOC-free products.